AOD Furnace Horizontal Continuous Casting

The company has complete refining equipment, 8 tons of medium frequency electric furnace, 8 tons of AOD refining furnace, horizontal continuous casting machine (single flow double flow).

Domestic first and only: "medium frequency furnace AOD furnace horizontal continuous casting" alloy production line. Meet the annual output of 24000 tons.

According to the actual situation of customers, we can provide customized master alloys with special compositions.

Refining Equipment

The company has complete refining equipment, including medium frequency furnace, electroslag furnace, AOD refining furnace, LF refining furnace, VD refining furnace. With ultra-low carbon, ultra-low phosphorus, ultra-low sulfur steel and high alloy steel production capacity. According to the actual situation of customers, we can provide customized master alloys with special compositions.

Vacuum Melting

There are 2 vacuum furnaces to meet customers' customization of special materials.

The molten steel melted in vacuum furnace has high purity and effectively removes nitrogen, hydrogen, oxygen and high impurity elements (zinc, lead, antimony, bismuth, tin and arsenic, etc.); the metal materials melted in vacuum induction furnace can obviously improve toughness, fatigue strength, corrosion resistance, high temperature creep performance and other properties.

Vacuum Equipment

Equipped with perfect melting, demoulding, cutting, coding, shot blasting, grinding, machining and other high-temperature alloy production line equipment.

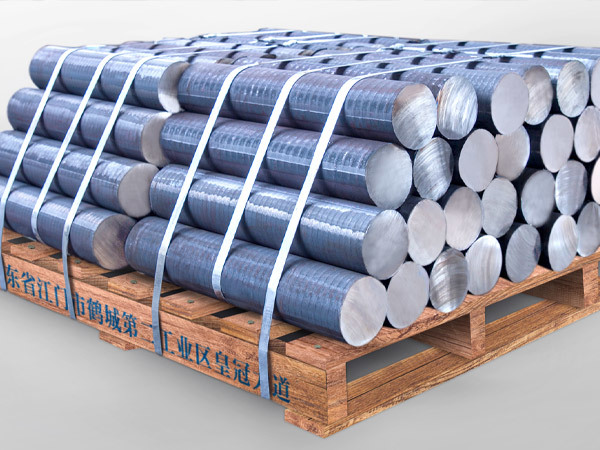

Product Show